For Jaguar Land Rover technicians operating within the legacy SDD (Symptom Driven Diagnostics) environment, the Vehicle Communication Interface (VCI) represents the critical link between diagnostic software and vehicle networks. While modern platforms have migrated to TOPIx Cloud and Diagnostics over Internet Protocol (DoIP), countless workshops still maintain SDD for servicing pre-DoIP vehicles (typically pre-2018). A common and potentially costly problem arises when using non-approved interfaces that cannot maintain stable communication during sensitive programming operations, leading to module corruption. The official JLR VCI, as an SAE J2534-1 compliant pass-thru device, is engineered specifically to provide the reliable, low-level communication required for successful module programming and CCF (Car Configuration File) editing within the SDD framework.

Technical Architecture of the JLR VCI

Protocol Compliance and System Integration

The JLR VCI is not a generic interface but an official Jaguar Land Rover tool designed to the SAE J2534-1 standard. Its primary function is to translate diagnostic commands from the SDD software into the specific electrical signals required by the vehicle's network protocols. Unlike generic interfaces, the JLR VCI contains proprietary firmware that ensures perfect timing and handling of JLR-specific communication sequences, which is crucial for module programming. It provides comprehensive support for the protocols used in JLR vehicles compatible with SDD:

- High-Speed CAN (Controller Area Network) – 500 kbps

- Medium-Speed CAN – 125 kbps

- ISO 9141-2 (K-Line)

- J1850 PWM

The hardware is specifically calibrated to handle the extended message lengths and strict timing requirements of JLR module programming procedures.

Hypothetical Step-by-Step Process for SDD Module Programming

A standard procedure for programming a key module using the JLR VCI with SDD is as follows:

- Vehicle Preparation: Connect an approved battery support unit (minimum 30A) to maintain system voltage above 12.5V throughout the procedure.

- Hardware Connection: Connect the official JLR VCI to the vehicle's OBD-II port and to the diagnostic laptop via the dedicated USB cable.

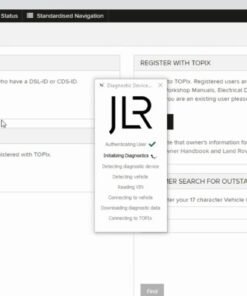

- Software Initialization: Launch SDD and allow it to complete the vehicle identification process. The software automatically recognizes the official VCI.

- Session Establishment: Navigate to the “Diagnosis” session type and follow the prompts to establish a secure connection to the target module.

- Programming Execution: Select the “Programmable Module Installation” routine. SDD will guide through the process of downloading and installing the correct software package to the module using the JLR VCI as the communication gateway.

- Configuration and Validation: Complete any required configuration steps and allow SDD to perform all validation checks before exiting the session.

Required Tool Ecosystem for JLR VCI Operations

Proper operation of the JLR VCI requires a complete supported environment:

- Official Hardware: The genuine JLR VCI interface with its specific USB cable.

- Power Management: A JLR-approved battery support unit or regulated power supply capable of maintaining stable voltage during extended programming cycles.

- Software Environment: A properly configured SDD installation with current software packages and valid JLR authentication.

- Specification-Compliant Laptop: A dedicated diagnostic laptop meeting JLR's specific requirements for SDD operation.

Common Technical Challenges and Resolution Strategies

VCI Communication Timeouts During Initialization

Problem: SDD fails to initialize communication with the JLR VCI, often displaying “Hardware not found” errors.

Solution: Verify the dedicated USB cable is securely connected at both ends. Ensure the official JLR VCI drivers are properly installed. Test the USB port functionality and try alternative ports if available.

Intermittent Connection During Programming

Problem: The programming process fails midway with communication errors, potentially risking module corruption.

Solution: This is frequently caused by voltage drop or insufficient system power. Confirm the battery support unit is properly connected and functioning. Ensure all vehicle electrical systems are switched off during programming. Use the shortest possible high-quality USB cable to minimize signal degradation.

Protocol Selection Errors

Problem: SDD cannot establish communication with specific modules despite successful vehicle identification.

Solution: While SDD typically handles protocol selection automatically, understanding the vehicle's network architecture is essential for troubleshooting. Verify which protocols the vehicle uses and ensure the JLR VCI is configured for automatic protocol detection.

FAQ: JLR VCI Technical Questions

Is the JLR VCI compatible with vehicles beyond the SDD era?

The JLR VCI is specifically designed for vehicles compatible with the SDD system, typically Model Year 2017 and earlier. For newer vehicles using DoIP (Diagnostics over Internet Protocol), the official JLR DA-DoIP VCI is required. Attempting to use the JLR VCI on DoIP-equipped vehicles will result in communication failure.

Can the JLR VCI be used with other diagnostic software?

While the JLR VCI is SAE J2534-1 compliant, it contains proprietary firmware optimized specifically for JLR's SDD software. Its performance with third-party diagnostic applications may be limited compared to generic J2534 interfaces, as certain JLR-specific communication sequences may not be properly supported outside the SDD environment.

What maintenance does the JLR VCI require?

The JLR VCI requires minimal physical maintenance but must be kept updated with the latest firmware revisions through official SDD updates. Technicians should regularly check for SDD software updates that include VCI firmware enhancements to ensure optimal performance and compatibility.

Conclusion: The Critical Role of the Official Interface

The official JLR VCI remains an essential tool for technicians maintaining legacy JLR vehicles within the SDD ecosystem. Its value lies in its guaranteed compatibility, reliable communication during critical programming operations, and seamless integration with JLR's diagnostic procedures. While the industry continues its transition toward DoIP and cloud-based diagnostics, the extensive population of CAN-based JLR vehicles ensures the ongoing relevance of this specialized interface. Investing in the genuine JLR VCI represents insurance against the substantial risks associated with module programming, particularly when performing complex procedures like CCF editing or module replacement.

For technicians and workshops undertaking sophisticated JLR OEM retrofits and advanced programming tasks on legacy vehicles, using the correct official tools is fundamental to success. For reliable equipment and expert technical support, we recommend exploring the solutions available at jlrupgrades.com.

Meta Description: Technical guide to the official JLR VCI – Jaguar Land Rover's SAE J2534 Pass-Thru interface for SDD diagnostics. Learn proper implementation for reliable vehicle programming and module configuration.

Tags: JLR VCI, SDD diagnostics, J2534 PassThru, Jaguar Land Rover tools, vehicle communication interface, module programming, JLR programming

Long Tail Keywords: official jlr vci for sdd, jaguar land rover approved diagnostic interface, sdd programming with j2534, jlr module replacement procedure, genuine jlr vci compatibility